Sedimentation

The pumped water is often containing solids that cause wear on pumps, valves and other dewatering equipment. This problem is very common in mines and tunnel construction sites. When pumping water that contains solids (like drill cuttings and sand), there is a risk of sedimentation in the system. A typical symptom is pipes and/or hoses that get filled with sediment, resulting in capacity losses. When the amount of solids increases, there is also an increase of wear on the pump.

The pumped water is often containing solids that cause wear on pumps, valves and other dewatering equipment. This problem is very common in mines and tunnel construction sites. When pumping water that contains solids (like drill cuttings and sand), there is a risk of sedimentation in the system. A typical symptom is pipes and/or hoses that get filled with sediment, resulting in capacity losses. When the amount of solids increases, there is also an increase of wear on the pump.

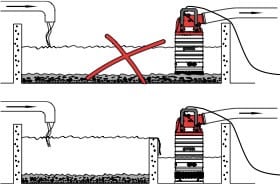

One way to prevent this is by using sedimentation tanks where the drill cuttings may settle while the rest of the water is pumped away. The tank needs to be as close to the source as possible, ensuring that the solids are pumped as short distance as possible where the solids can settle in peace. To ensure the efficiency of the sedimentation tank, it needs to have as big surface area as possible. The more solids present in the water, the more careful the design of the sedimentation system is necessary.

For applications where solids can not be avoided, there are recommendations for the velocity of the medium in the discharge line:

Mixture |

Min. velocity in discharge line |

| 1. Water + coarse gravel | 4 m/s (13.1 ft/s) |

| 2. Water + gravel | 3 m/s (11.5 ft/s) |

| 3. Water + sand: | |

| Sand particles < 0.1mm (0.004 in) | 1.5 m/s (8.2 ft/s) |

| Sand particles < 0.6mm (0.024 in) | 2.5 m/s (4.9 ft/s) |