Oden Anläggningsentreprenad

Stockholm, Sweden

Grindex new series of dewatering pumps are designed to last three times longer in abrasive applications compared to previous pump generations. In this case study from Sweden, they are up for a tough test.

One of the critical factors for the building of 3,000 new homes within a few years are the seven submersible dewatering pumps from Grindex installed deep in the bedrock below south Stockholm. These are keeping the "Skanstull-Solberga" high voltage cable tunnel dry.

-"We are working with five parallel fronts at the moment, this enabling us to maintain a pace of around 80 to 100 metres per week", explains Peter Ahlgren at the construction company Oden Anläggningsentreprenad. Peter is the blasting supervisor for the new high voltage cable tunnel.

Room for more residents

The tunnel is one of a number of major construction projects in progress around Stockholm. Ten kilometres of 220 kV high voltage cable cutting straight through residential areas will now be replaced with cables laid through the new tunnel. This will provide sufficient attractive land near Stockholm city for some 3,000 new homes.

Pump breakdown is not an option

Two of the five tunnel fronts are blasted from the middle outwards and accessed via a subterranean transport tunnel. Work on both fronts takes place in turns, blasting on one while clearing away the rubble on the other. During our visit at the west front, two men are working beside a drilling rig.

Drilling has just stopped and some 65 pieces of four metre deep holes covering an area of 20 m2 are being filled with explosive. The rock is granite with seams of diabase, a very hard stone. Wear on the drill bits is harsh and the drills need large quantities of cooling water. After cooling the drills, the water runs down to the tunnel floor. Reliable pumps are needed to keep operations going, these having to operate continuously to keep the water out. A breakdown would have immediate and serious consequences.

-"Without reliable pumps we can't work and the project would be immediately and adversely affected. It is very important for the pumps to work properly if we are to keep up to the schedule," continues Peter Ahlgren. "We need to pump out 300 litres of water every minute when we're drilling. It's 50 metres to the surface, so the pumps need to stand up to a good deal of strain, but so far they have functioned well and we are working according to plan."

Put to the test

Wear and tear on the pumps is considerable. The water near the drilling rig is full of drill cuttings. The effect this has can be compared to liquid sandpaper which rubs constantly on the internal parts of the pumps.

-"We are using two models from our latest pump series" says the Swedish sales manager from Grindex, Per-Åke Jägrén. These are especially strong and hard wearing and built to withstand these kinds of conditions. They incorporate an entirely new design, where the abrasives in the water are kept away from the sensitive parts of the pump. Our pumps have really been put to the test in this tunnel project and have demonstrated that they can meet everything expected of them. What we are witnessing here confirms our own tests."

The water is pumped up from the lowest parts of the tunnel pipe to ground level, 50 metres up. The pumps are working in stages using sediment tanks along the way. At this point most of the remaining drill cuttings are separated from the water and the water pumped on upwards is in large clean. Water samples are taken regularly to ensure that municipal water regulations are obeyed.

Maintaining standards

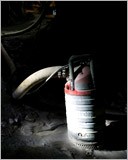

The pump closest to the drilling rig, a Grindex Major, is the unit exposed most to the drill cuttings in the water.

"This water is almost like gruel," Peter Ahlgren tells us. Grindex recommend 2000 running hours between services, but we service the pumps every 1500 hours to be on the safe side. In practice, this means the shortest service interval for the pump system is two months. However, we carry out a standard daily inspection of the equipment." Peter confirms that Grindex information about servicing routines is correct.

-"We've been operating at full speed down here since the end of April and everything has worked properly," he tells us. "We have now come some way into the tunnel construction and are working at maximum speed. It is important to us to be able to maintain this tempo and reliable equipment is essential. If one of them were to stop, everything else would stop too. You could say that the chances of Stockholmer's getting new housing depend on having the right kind of pumps down here in the tunnel.

Facts about the pumps

Several Major and Master pumps are used in the tunnelling work. A Major N-pump can deliver over 35 litres/second (over 2 cubic metres per minute) in tough environments and work continuously without monitoring. The Master H pump is capable of a delivery head in excess of 45 metres.